Transactional Content Management

PRODUCTS

-

Werum PAS-X Packaging optimizes efficiency, compliance, and transparency in your packaging line, combining OEE monitoring, electronic batch recording, and track & trace in a single scalable system.

-

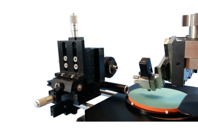

NOVA™ Profile Inspection Module provides real-time monitoring, helps positioning, confirms completion, and measures endface geometry for fibers, waveguides, and arrays.

-

Expediting the customer journey from discovery all the way through commercial release.

-

The 132M HC sets the standard for performance, precision, and reliability. This wrap-around labeler applies labels to cylindrical products with the utmost accuracy at the highest performance.

-

Werum PAS-X Savvy accelerates bioprocessing with real-time data management, visualization, and analysis—enabling agile development, robust decision-making, cost reduction, and consistent quality across pharma and biotech production lifecycles.

WHITE PAPERS AND CASE STUDIES

-

Designing Drainage For A Solar Farm In The UK With Strict Requirements

Tasked with strict drainage compliance requirements for a solar panel farm in the UK countryside, Project Centre used their brand-new drainage software to streamline design workflows and achieve the results they needed.

-

University Of Ottawa Relies On The BEAMAGE Series To Measure Laser Profiles

The University of Ottawa lab successfully used beam profilers to improve Power-Over-Fiber receiver chip development, ensuring precise, efficient laser measurements for advanced photonic research.

-

Still Using Paper Diaries To Capture PRO Data? Read This.

Access real-world examples of how electronic patient-reported outcome measures (PROMs) optimize data quality and reliability and improve the statistical power of trial data.

-

Leveraging High-Pressure Sterile Filtration For Highly Viscous Solutions

This research demonstrates the potential of high-pressure sterile filtration to enhance efficiency, reduce waste, and accelerate the development of innovative therapies.

-

GSK And Medable Discuss The Next Phase Of DCTs

GSK and Medable share the value of embedding DCTs into strategic goals to enhance trial accessibility, diversity, and efficiency.

-

Digital Transformation - The Power Of Your Data

Discover how you can circumvent numerous recirculations during the ultrafiltration process step, boost downstream bioprocess yield, and identify and resolve process inefficiencies.

-

Driving A High-Adherence LTFU Trial Without An EDC

Discover how our partnership with a client was able to deliver a ten-year long-term follow-up (LTFU) trial that delivered an over 90% adherence rate while keeping trial costs low by not using an EDC.

-

Effective Recruitment Capabilities And Outstanding Customer Service

Hear from many customers who commend OpenClinica's effective recruitment capabilities, outstanding customer service, and adept problem resolution.

-

Electronic Batch Reporting

Learn how a CDMO automatically created a comprehensive batch report model to drive their reporting and speed root cause identification of quality failures with an Industrial DataOps software solution.

-

BioIVT Collaborates With IDBS To Deploy IDBS E-WorkBook And Reduce Study Cycle Times

Learn about a collaboration that has enabled BioIVT to enhance efficiency and responsiveness to its biopharmaceutical clients.

-

A Digital Solution Embeds Quality Into Cellular Therapeutics Production

Discover how Dendreon cut review and release time by nearly 50% while maintaining a 99% right-first-time rate, which boosts collaboration, visibility, and operational efficiency across teams.

-

Simplify CAPA In 7 Steps

Discover how to streamline corrective action/preventive action (CAPA) management in regulatory environments in 7 steps.

NEWS

-

Fiber-Sensing Technology Can Provide Early Warning For Volcanic Eruptions4/24/2025

The Reykjanes Peninsula at Iceland's southwestern edge is one of the country's most populated regions, and it is also one of the most volcanically active. In 2024, sensing technology developed at Caltech was deployed in the region to study the motion of subsurface magma and its eruption into lava on the surface.

-

Controlling Quantum Motion And Hyper-Entanglement5/22/2025

Manuel Endres, professor of physics at Caltech, specializes in finely controlling single atoms using devices known as optical tweezers.

-

U Of I's New Controlled Environment Research Facility Advances Indoor Farming With Stakeholder Input12/15/2025

Bathed in an otherworldly purple glow, James Santiago points to a curled leaf at the base of a spinach plant.

-

University Of Cambridge Chooses AIXTRON Tool For Next Generation 2D/Layered Materials-Based Photonic Devices7/15/2025

The University of Cambridge in United Kingdom has purchased a Close Coupled Showerhead system for 2D materials from AIXTRON SE for its research and development in the field of photonics and optoelectronics.

-

Low-Noise Transducers To Bridge The Gap Between Microwave And Optical Qubits3/19/2025

In the effort to build superconducting quantum computers, researchers around the world are working to develop electrical circuits that operate in the microwave domain using individual particles of microwave radiation, or microwave photons, as qubits—the basic building blocks of quantum computing.