Capture

PRODUCTS

-

Guide operators through dynamic workflows from equipment startup to maintenance.

-

The Fairbanks Nijhuis two-stage horizontal split case pump offers long, reliable service with no maintenance. Designed for general liquid pumping and booster applications.

-

Torque wrenches simplify coaxial connector tightening, preventing over-torque and ensuring optimal performance. Color-coded handles and bands make selection easy, and various torque settings are available.

-

Our Approach

At Southern Star Research, we have extensive experience across all aspects of clinical operations and a wide range of therapeutic areas. We specialize in providing flexible, high-quality, and custom solutions that help you deliver regulator-ready data on time and at a predictable price.

As a large proportion of our clients are geographically dispersed, we understand how important it is to be able to trust that your CRO is working in your best interests. That’s why we pride ourselves on building strong, transparent, and close relationships with our clients.

Our team of experts will guide you through the clinical trial process using a proactive and collaborative approach, ensuring that your stakeholders are always informed, in control, and confident throughout the journey.

-

Compliance solutions for product development agility and audit readiness.

WHITE PAPERS AND CASE STUDIES

-

Understanding Ultrapure Water, Difficulties With pH Measurement

By gaining insights into the diverse types of pH measuring analyzers and sensors, companies can make informed decisions to enhance their UPW management strategies and drive operational excellence.

-

Quick And Easy Pipe Repair In Virginia Saves Thousands Of Dollars

Learn how JCSA efficiently replaced ten dresser-style couplings on a 16" steel pipe spanning a 600-foot bridge using the versatile HYMAX VERSA coupling, enabling a quick and cost-effective repair without removing the pipe.

-

Periodically Poled Lithium Niobate Used In Spectroscopy

Explore how PPLN's superior nonlinear properties, broad tunability, and high sensitivity drive advancements in various spectroscopic techniques and applications.

-

Warehouse Logistics Challenges? UWB Says, "Hold My Beer"

Struggling with outdated RFID systems, see how Budweiser Budvar Brewery turned to Ultra-Wideband (UWB) technology to tackle its complex logistics challenge.

-

Achieving Complete Destruction Of PFAS Using electraCLEAR Process

In early 2023, Lacks Enterprises Inc., a large automotive component supplier in the midwestern US, engaged Axine to address destruction of legacy PFAS compounds in wastewater from its manufacturing processes.

-

Facilitate Handling Of Bulk Powders With Dry Granulation

Handling bulk powders in manufacturing presents serious challenges—from unpredictable caking to safety risks—that can disrupt workflows. Discover solutions to streamline operations and protect your team.

-

Rescuing A Global Program For NDA Success

Explore the collaboration that enabled FDA approval of a novel chronic-condition therapy, rescued a high-risk program, and demonstrated a unified “one-team” approach by reworking the sponsor's SAP.

-

MBR Solutions For Modern Industries

This white paper will explore advanced, sustainable wastewater management systems that align with your business's growth trajectories and emergent needs.

-

How To Unlock The Secret To Repeatable, Scalable Low Turnover

Here, we explore the evolution of a 10-year partnership and extrapolate the principles that create cohesive teams and minimize turnover.

-

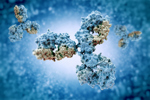

Modelling TPDs Utilizing Computational And Medicinal Chemistry Approaches

Through a carefully executed strategy, see how we identified novel degrader molecules with the right physicochemical properties to achieve robust degradation of the target Protein of Interest (POI).

-

Bioconjugates – An Increasing Diversity, A Blossoming Of Therapeutic Applications

Harness the power of bioconjugation to revolutionize targeted therapies, enhance drug efficacy, and reduce side effects, paving the way for more precise and effective treatments across a range of diseases.

-

Revolutionizing Wastewater Management In Four Cities Through Water Mixing

Historically, lift station operators have turned to chemical treatments as the primary means of managing grease buildup. However, these methods carry inherent drawbacks.

NEWS

-

Fast Code Reader For Simple And Reliable Sample Identification2/18/2026

Meet the Micronic Rack Reader DR515, a compact, simple and high-performance 2D code scanning solution designed to enhance efficiency and accuracy in modern laboratory environments.

-

Automated Handling For Liquid And Solid Samples6/18/2025

Micronic is proud to introduce the second-generation of the Tube Handler HT500, featuring an enhanced design for even more efficient and reliable sample handling in the laboratory.

-

MyFitnessCoach Enhances Food & Macro Tracking With AI Insights & Smart Barcode Scanning1/15/2026

MyFitnessCoach, a rapidly growing digital fitness and wellness platform, is enhancing the nutrition experience for users worldwide through advanced food calorie tracking, intelligent macro tracking, and AI-powered insights.

-

FineLine Technologies Acquires Digi-Trax Deal Marks FineLine Expansion In Healthcare Industry12/10/2025

FineLine Technologies announces its acquisition of Digi-Trax Corp., a leading provider of healthcare labeling and identification solutions that support safety, traceability and compliance in the blood and cell-therapy supply network. Digi-Trax will operate as FineLine’s new Healthcare Division.

-

Tiponline POS Launches Smart POS Features To Support Halal Restaurants In Canada And The USA6/2/2025

Tiponline POS, a cloud-based restaurant management platform, has expanded its smart point-of-sale (POS) solutions to support halal restaurants across Canada and the United States.