Utilizing Custom Solutions For Robotics & Automation

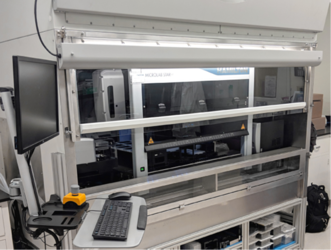

In partnership with NuAire’s custom products engineers, Sanofi developed novel biological containment solutions that helped accommodate automating lab workflows such as robotic liquid handling. According Sanofi Pasteur’s head of automation, most biological hoods that are used in the lab are typically designed to operate for an individual with small equipment inside. For our application we still needed the biological containment, but in a large-scale format to accommodate our automation platforms. Standard, off-the-shelf biological safety cabinets (BSCs) usually range from three to six feet wide with a work zone depth of 20 inches, which could not safely house the robots and interactions in clean conditions.

In the past 20+ years, NuAire has built oversized class II custom biosafety cabinets as large as 14 feet wide. Their engineers also designed containment solutions that combined both standard and custom BSCs. NuAire and its engineering team design and manufacture custom cabinetry critical for keeping unique laboratory projects on track. They do this by prioritizing customers’ needs and building solid problem-solving relationships. NuAire’s standard line of biosafety cabinetry have long held an enviable reputation of safety by conforming to the most rigorous standards set by regulatory organizations.

NuAire says that you’ll find brilliant yet practical design with keen attention to detail in every phase of the fabrication and assembly process; you’ll always receive thoroughly tested equipment at outstanding value, and with dependable customer service guaranteed.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of ECM Connection? Subscribe today.