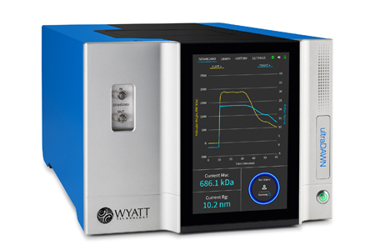

ultraDAWN™ Real-Time Multi-Angle Light Scattering

ultraDAWN™ measures multi-angle light scattering and reports the results – molecular weight, size and particle concentration – in real time.

A breakthrough in process analytical technology for production of nanoparticles, biopharmaceuticals and polymers.

Real-Time Multi-Angle Light Scattering

With RT-MALS, critical quality attributes (CQAs) can be monitored directly, for rapid feedback on product and process quality.

Benefits of RT-MALS

- Accelerate process development and scale-up

- Increase yield, reduce overall time until lot release

- Maintain product quality with confidence

Where MALS and PAT meet

The ultraDAWN is a unique member of the DAWN® family of MALS instruments. Instead of residing in the analytical lab like Wyatt’s other MALS instruments, it is adapted to pilot plants and production environments. OBSERVER™ software is used to calculate and report molar mass and size, 30 times per minute, as opposed to ASTRA’s post-separation, detailed off-line analysis and reporting.

PAT instrumentation is well-known and typically monitors process parameters such as pH, temperature, pressure and feedstock, which are tied indirectly to product properties and quality. UltraDAWN revolutionizes process development with its continuous, direct measurements of actual product properties.

Built in the NEON platform, ultraDAWN provides an intelligent user interface indicating real-time and time sequences of molar mass, size and/or particle concentration as well as system health diagnostics and event history. With photodetectors at eighteen scattering angles plus one more to measure light transmitted through the flow cell, the ultraDAWN provides a solution for:

- Macromolecules: Mw from 103 to 109 g/mol and Rg from 10 to 250 nm

- Nanoparticles: Z-average radius from 10 to 250 nm and corresponding particle concentration (concentration range depends on particle size)

UltraDAWN offers versatile options for PAT, including:

- In-line or on-line configuration

- Process or slipstream flow rates from 0.1 mL/min to 5 mL/min

- Integration with production control software via OPC