Glass Ampoule Forming Lines

Process stability, high efficiency and customizable features are crucial issues related to glass packaging manufacturing. Our ampoule forming line perfectly matches these needs, guaranteeing the highest performance thanks to cutting-edge capabilities, such as its automatic inspection system and electric rotational oven, which provides higher product handling stability.

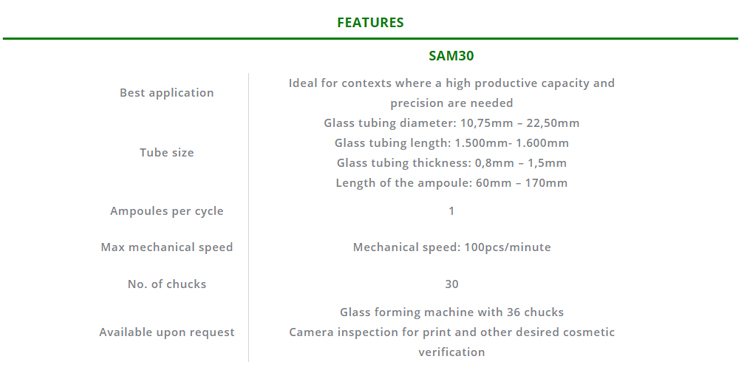

Features

- Modulating burners for tip forming installed after the high performance NOVIS Inspection System

- Self-centering chucks, to guarantee shorter format change over time, and lower maintenance thanks to their improved lifetime

- After-forming line complete with cooling system, length and concavity inspection system

- Tear-off and glazing steam unit

- Score break unit

- Packaging line with an automatic turntable for five packing positions

- Aspiration module to remove glass particle discards

- Color ring unit dedicated to serigraphy up to three rings

- Cutting unit, OPC unit and OPC check camera

- Print unit and drying color unit

High quality, high reliability

- The automatic camera inspection system for dimensional controls allows the customer to constantly monitor the line performance and to reach the highest process efficiency

- The electric rotatational oven with a smaller footprint enables to print up to a few millimeter from the bottom of the ampoule and to gain a higher product handling stability in comparison to traditional walking beams

- The self-adjusting heat control system on the oven gathers information and automatically adjusts the heating elements for an ideal thermal curve

- Our machines are designed to guarantee high quality, high process stability, high speed of output, facility of use and the control of each step of production, from tube loading to serigraphy

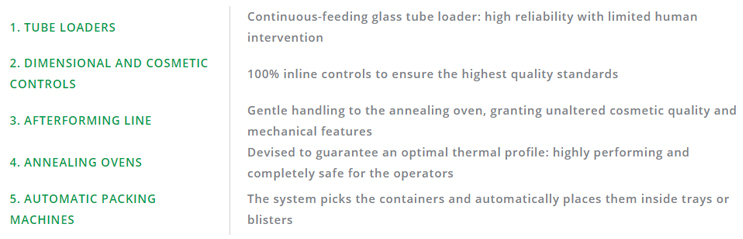

A complete production line or stand-alone modules

Stevanato Group glass converting lines are available as a turnkey package, including the forming unit and other processing equipment, or as stand-alone modules. We also offer fully automatic washing equipment to remove particles from the glass and reduce cosmetic defects. Click on the modules below to learn more.