3D Systems Accelerates Service Team Performance With Service Intelligence Solution

For more than 30 years, 3D Systems has developed and delivered cutting-edge 3D printers. Recently, its customers have evolved from using 3D printing technology primarily for prototyping towards developing manufactured products for end users. As a result, providing exceptional service became even more critical.

"We had to dramatically change our services organization to keep pace with our customer's need for much quicker response time,” said Mark Hessinger, VP of Global Customer Services at 3D Systems.

EVOLVING TO MEET CUSTOMER DEMAND

Mark sought a technology partner to achieve three main goals:

- Provide its global network of service pros better access to siloed information.

- Implement tiered support so its specialists weren't spending precious hours resolving issues that could be handled by junior staff.

- Onboard new service techs quicker to get them out in the field solving complex service problems.

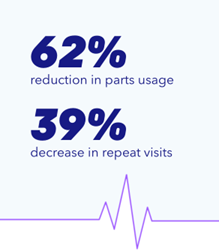

3D Systems turned to Aquant’s service intelligence platform to deliver data-driven insights to its service team, empowering them to perform better and solve issues faster.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of ECM Connection? Subscribe today.