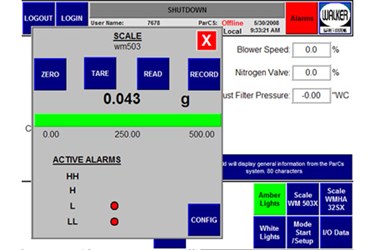

Building Safety Into Isolator Controls Systems

As isolators become more customized to meet the requirements of specific Pharmaceutical processes, the controls systems have been challenged to provide more safety and flexibility.

A process may require the isolator to have inflatable gaskets and provide oxygen monitoring. To meet the challenges, Walker Barrier Systems has designed a controls system that provides:

Automated start up sequence

- It is important to have an automated start up sequence to be certain that the isolator is sealed and in leak tight. This will assure the operators safety.

- Door seal test and pressure decay test is automatically performed before the isolator goes into “run” mode.

access the Case Study!

Log In

Get unlimited access to:

Trend and Thought Leadership Articles

Case Studies & White Papers

Extensive Product Database

Members-Only Premium Content

Welcome Back! Please Log In to Continue.

X

Enter your credentials below to log in. Not yet a member of ECM Connection? Subscribe today.

Subscribe to ECM Connection

X

Subscribe to ECM Connection